Servo valves in hydraulic systems

Valves play a vital role in hydraulic systems. Not only is it a key device for controlling the flow of fluid, but it also enables the opening and closing of flow, changes in direction, increases and decreases in speed, as well as the release and regulation of pressure. However, for certain piping systems that require extremely high precision, simple manual valves may not be able to meet the demand. This is when servo valves become the engineers' first choice, with their high-precision control capability enabling hydraulic systems to operate more efficiently and stably.

▣ The Importance of Servo Valves

Servo valves, a high-performance device, are designed to manipulate complex piping systems. When faced with complex piping systems, manually operating valves is often difficult to ensure accuracy and the process is cumbersome and difficult to manage. Especially in applications involving extreme quantities, pressures, temperatures or chemicals, manual control is not only time-consuming, but also poses potential safety risks. The introduction of servo valves, on the other hand, greatly simplifies the management of piping systems, especially the operation of closed-loop systems.

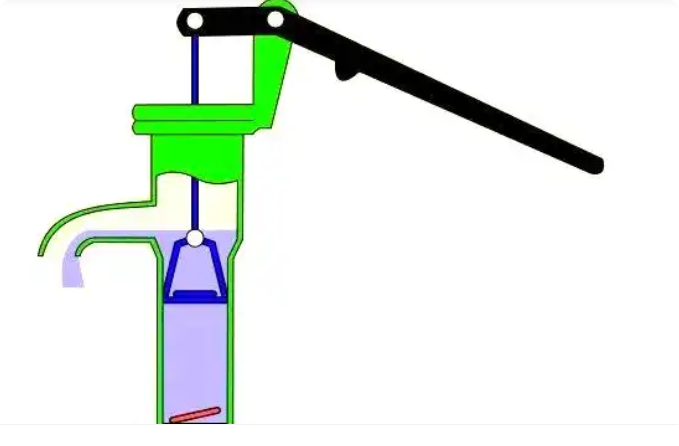

▣ Servo Valve Principle of Operation

Their electrical signal-driven and remotely operated nature allows the user to easily adjust the flow rate by sending low-power signals through the digital control panel. These signals are amplified by an amplifier and are sufficient to drive the servo valve to change position, which in turn manipulates the actuator (similar to a simple handwheel) to achieve the desired flow change. Due to the closed-loop design of the system, the feedback mechanism ensures that the servo valve responds more precisely to commands.

▣ Servo Valve Application Areas

Servo valves, a high-performance device, are used in a wide range of applications because of their high precision and control. Designed with efficiency in mind, servo valves are often installed in systems that require precise control. They are used in a wide range of applications, including regulating fluid flow in hydroelectric power plants and oil and gas extraction sites, as well as controlling fuel flow in aircraft engines, and even play a key role in blow moulding or hollow plastic manufacturing processes. However, due to the amount of work involved, servo valves are often expensive. In practical applications, many engineers may choose to use proportional valves instead of servo valves depending on their needs.

▣ Servo Valve Market and Brands

Of course, in some cases, the cost of purchasing a new servo valve may cause an engineer to seek professional repair services when a servo valve fails. Whether purchasing a new valve or seeking repair, there are numerous high-quality servo valve brands available in the domestic and international markets, such as the U.S. MOOG Moog, the German REXROTH Rexroth, the U.S. PARKER Parker and so on. Domestic servo valves in technology, although a late start, but the momentum of development is rapid, and has a broad space for improvement. At present, the main domestic servo valve manufacturers include Xiangyang Hangyu Electromechanical Hydraulics, Shaanxi Qinfeng, and Beijing 18 Institute. Next, we will explore the application of servo valves and its importance from a variety of perspectives.