History and Classification of Servo Valves

1.1 Development history of servo valves

It is generally believed that electro-hydraulic servo technology originated in the early 1940s. In the later stage of World War II, due to military needs, especially the promotion of jet fighters, electro-hydraulic servo valves continued to develop and improve. Up to now, servo valves have become an indispensable technical equipment.

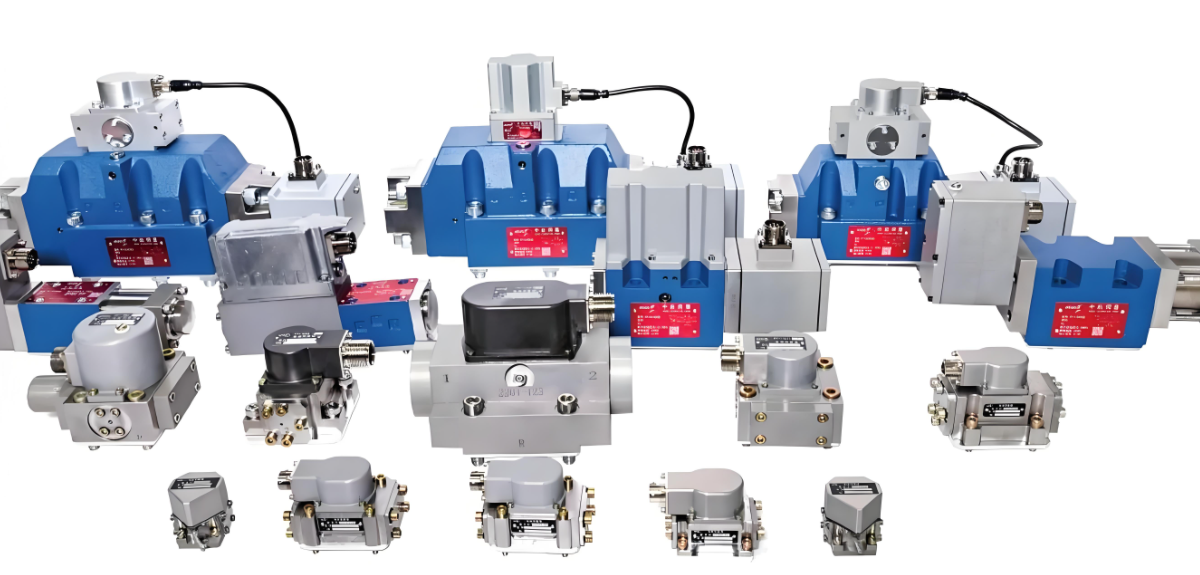

Three types of servo valves

The common servo valves on the market can be mainly divided into three types based on their principle and structure: dual spray mechanical feedback (MFB), jet tube electric feedback (ServoJet), and direct acting (DDV). These three types of servo valves each have their own characteristics and advantages, and are known as the "three swordsmen of servo" in the industry. Among them, the dual spray mechanical feedback servo valve is particularly outstanding in performance and can be called the "servo leader". It is worth mentioning that the MFB servo valve follows the ISO10372 installation bottom standard, which makes it an indispensable position in the market.

However, for jet tube and direct acting servo valves, although they also have the performance or characteristics of servo valves, their installation bottom standards are the same as conventional valves, namely ISO4401. Therefore, in a sense, we can refer to these two types of valves together with the aforementioned servo performance proportional valves as servo proportional valves or proportional servo valves.

In summary, although the naming of valves for electromechanical converters may vary, it is important to clarify their applications and service targets. Therefore, here we still refer to valves with servo valve characteristics and servo performance as servo valves.

Innovative Design of Servo Valve

Partial guide jet tube and dynamic pressure feedback technology

Of course, the types of servo valves are not limited to the three mentioned above. Once, dynamic servo valves were gradually phased out due to their large size and performance limitations. However, based on it, engineers have successfully developed a new type of servo valve - direct acting (DDV), also commonly known as moving iron servo valve. This servo valve has significantly improved in performance and has become a leader in the field of servo valves.

In addition, by combining the advantages of dual spray barriers and jet pipes, engineers have further developed a biased jet pipe servo valve, as shown in Figure 5. This servo valve is innovative in both performance and structure, bringing more possibilities for the application of servo valves.

Characteristics and challenges of rotary valve servo valve

In addition, EMG also provides a servo valve with a rotary valve structure, model EMG SV1-10. The servo valve with this rotary valve structure has its unique design and performance, providing engineers with more choices.

However, whether using a torque motor as the dual spray stop structure of the electromechanical converter or a jet tube servo valve using a jet motor, there is a common problem: they both need to lose a portion of the pilot flow, which is classified as internal leakage. Although internal leakage may cause high-frequency noise, it is clearly not the result we expected. In addition, although the DDV servo valve using servo motors has excellent dynamic performance, its bi-directional working characteristics also limit its available stroke. Therefore, the stroke of DDV valves is usually small, only about ± 0.5mm, which to some extent limits the flow capacity and resolution of the valve.

The challenge of dual spray servo valve

Manufacturing complexity and influencing factors

Next, we will explore the working principle of MFB dual nozzle baffle servo.

Figure 9 shows a schematic diagram of the working principle of the dual spray stop structure servo valve. However, the manufacturing and production of this servo valve is exceptionally difficult, mainly due to its performance being affected by numerous variables, and there are complex coupling relationships between these variables. Every step from part processing to assembly and even testing may be affected by changes in a certain variable, which can affect the certainty of the final result. For example, in the MFB structure, small changes in the spray distance may be due to dimensional errors in part processing or differences in baffle thickness, or may be affected by the nozzle assembly position.

In addition, the air gap of the armature, the stiffness of the tube spring, and the feedback rod after the combination of multiple parts are variables that are difficult to stably control, and they all have a significant impact on the static and dynamic performance of the valve. Therefore, the manufacturing of servo valves requires precise factory debugging to integrate these factors. It is worth noting that MFB servo valves are complex to manufacture and their performance is easily affected by multiple variables, such as machining errors in parts and mechanical fit after assembly. Fine tuning is required to ensure stability.

In addition, the magnetization strength of the magnetic conductor, the assembly of the sealing ring, and the torque of the installation screws all have an impact on the performance of the servo valve. Due to space limitations, this article only briefly lists a few key factors for readers' reference. If you are interested in further understanding, you can refer to relevant literature materials. It is worth noting that once these servo valves are disassembled, they can hardly be restored to their original state, and even if repaired by professional manufacturers, they can only meet the factory standards.