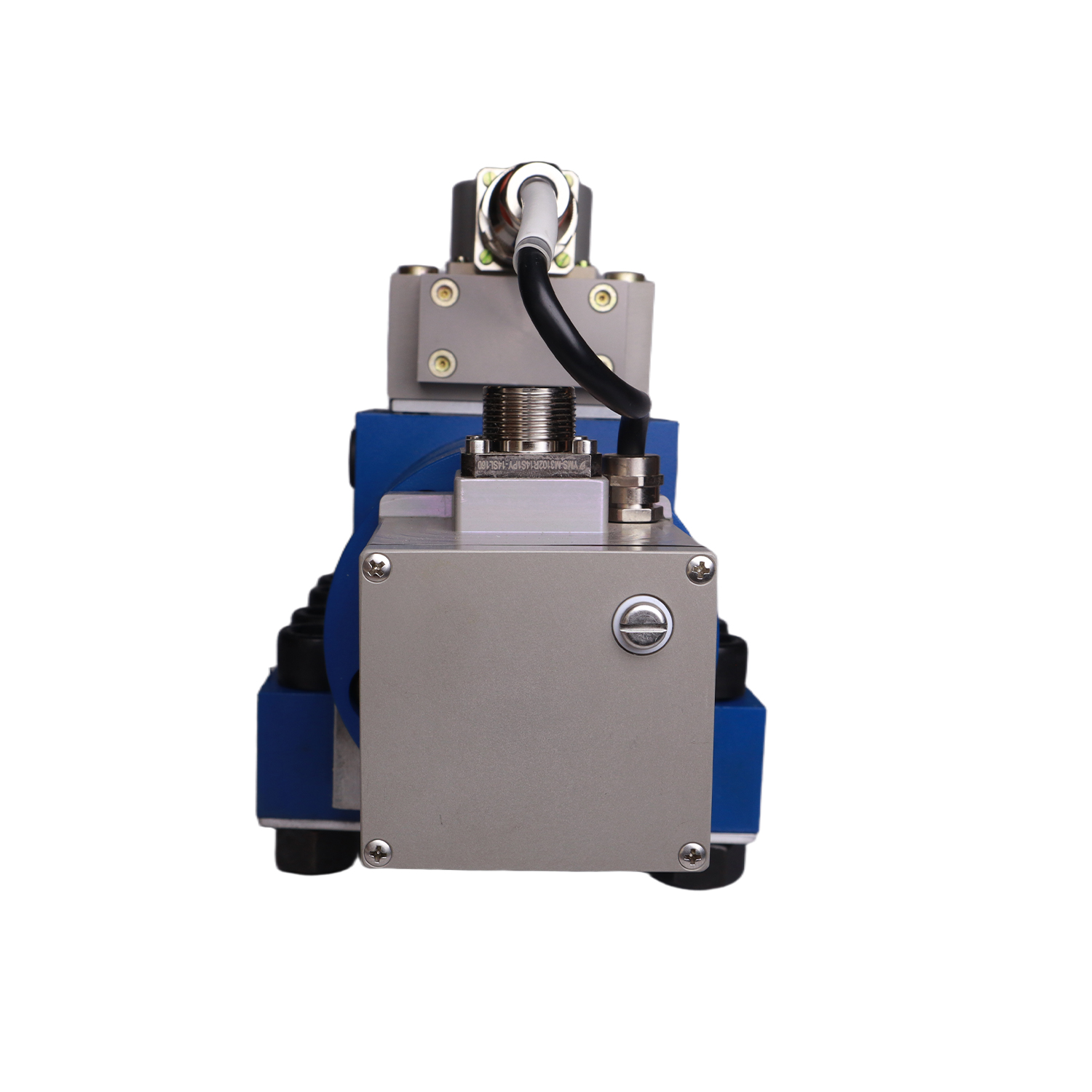

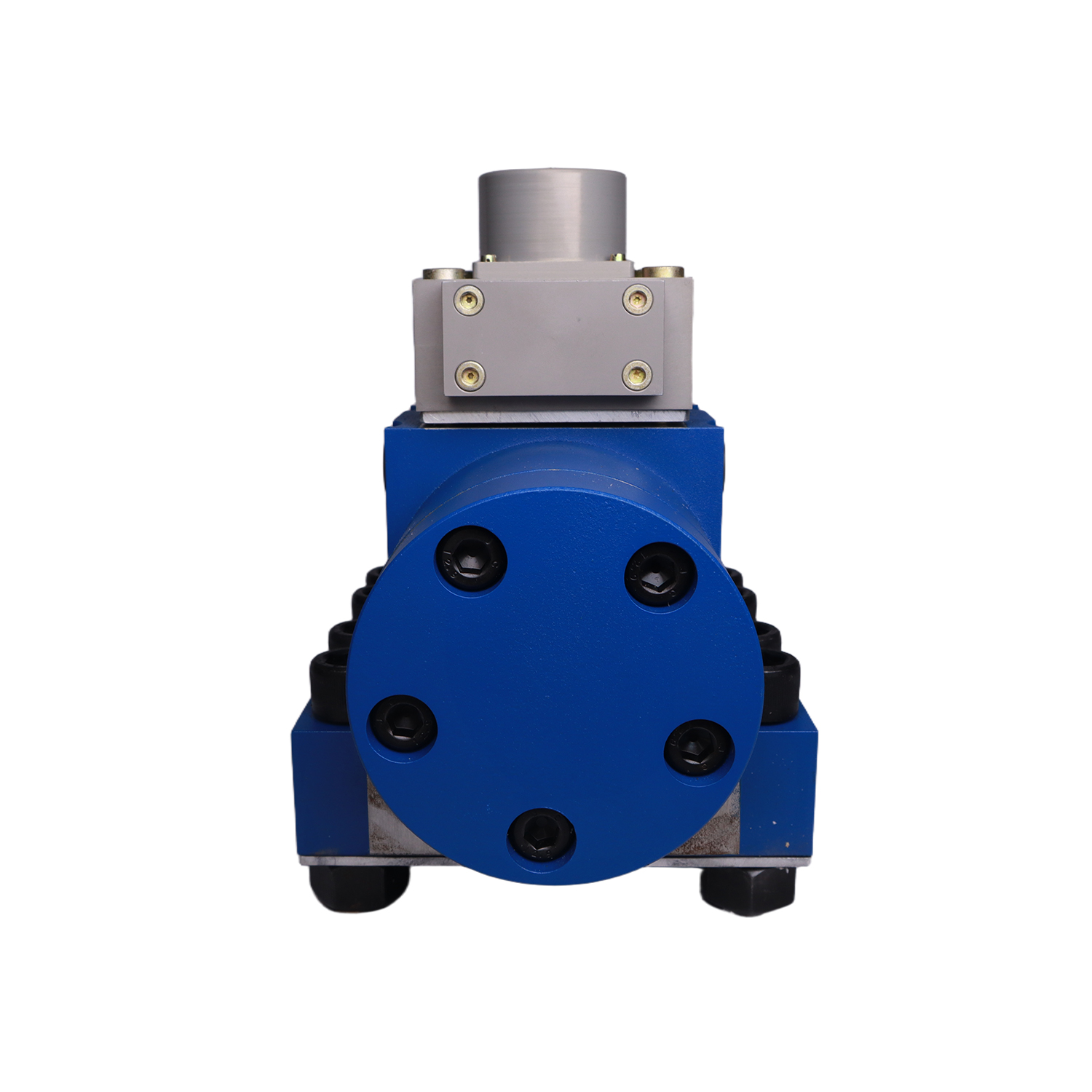

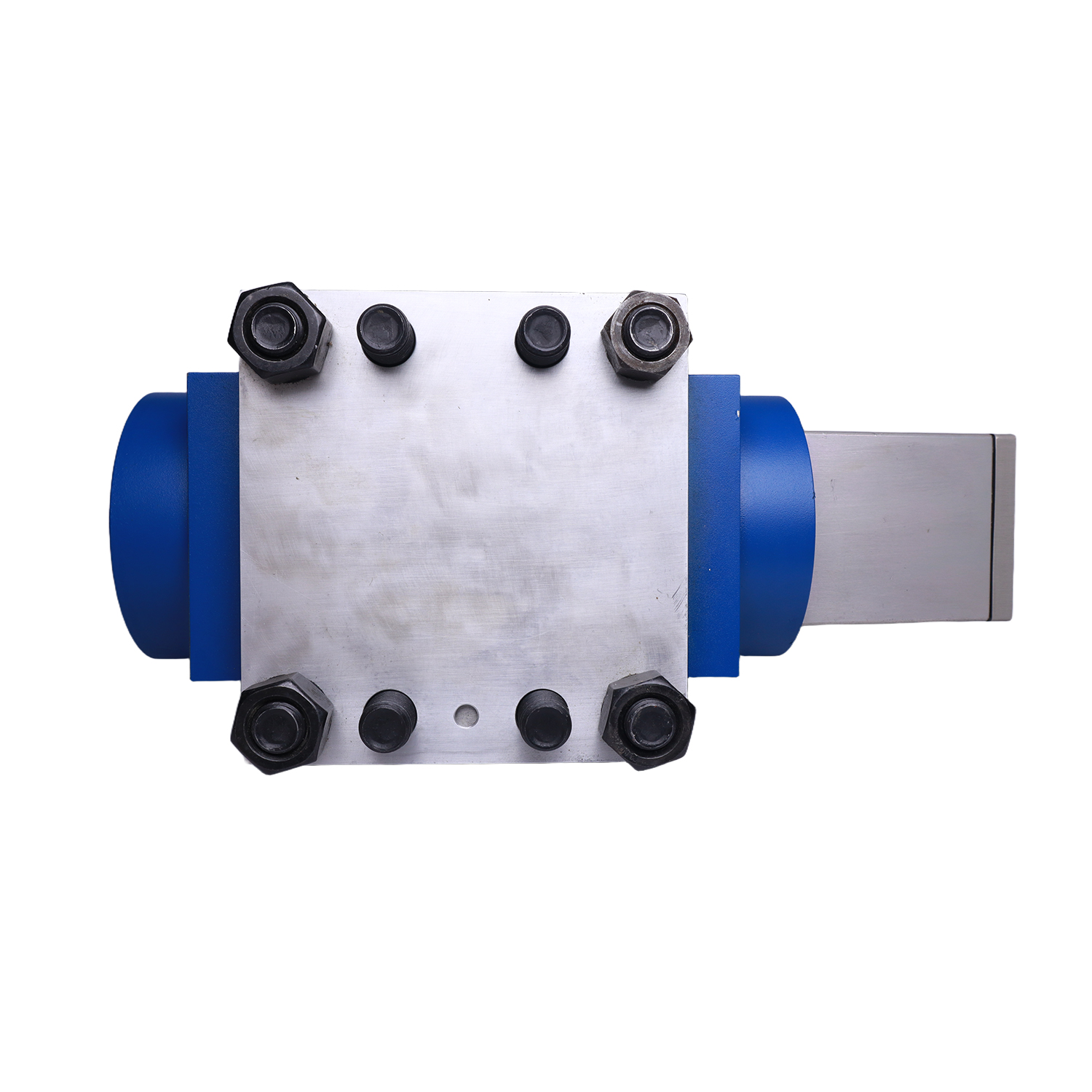

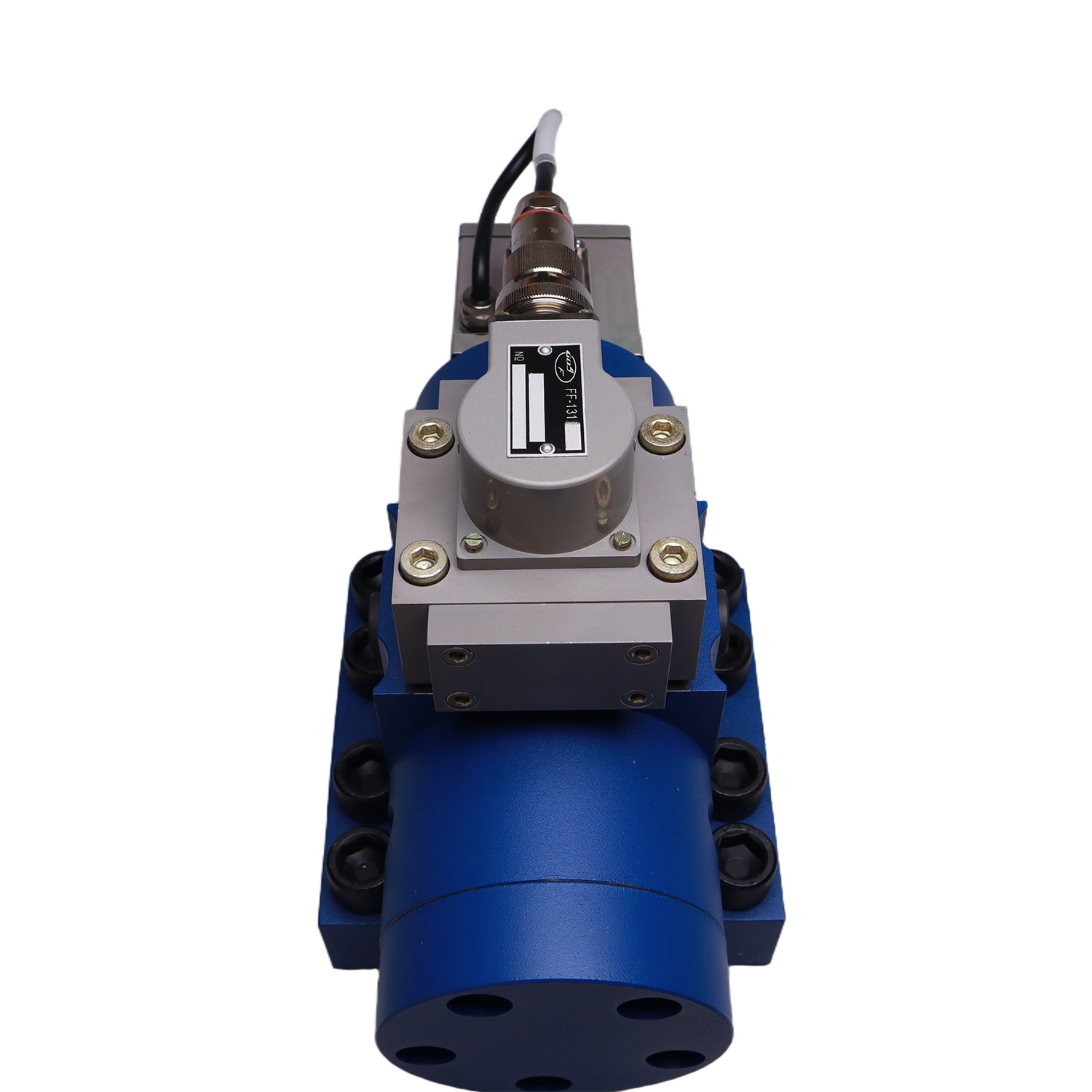

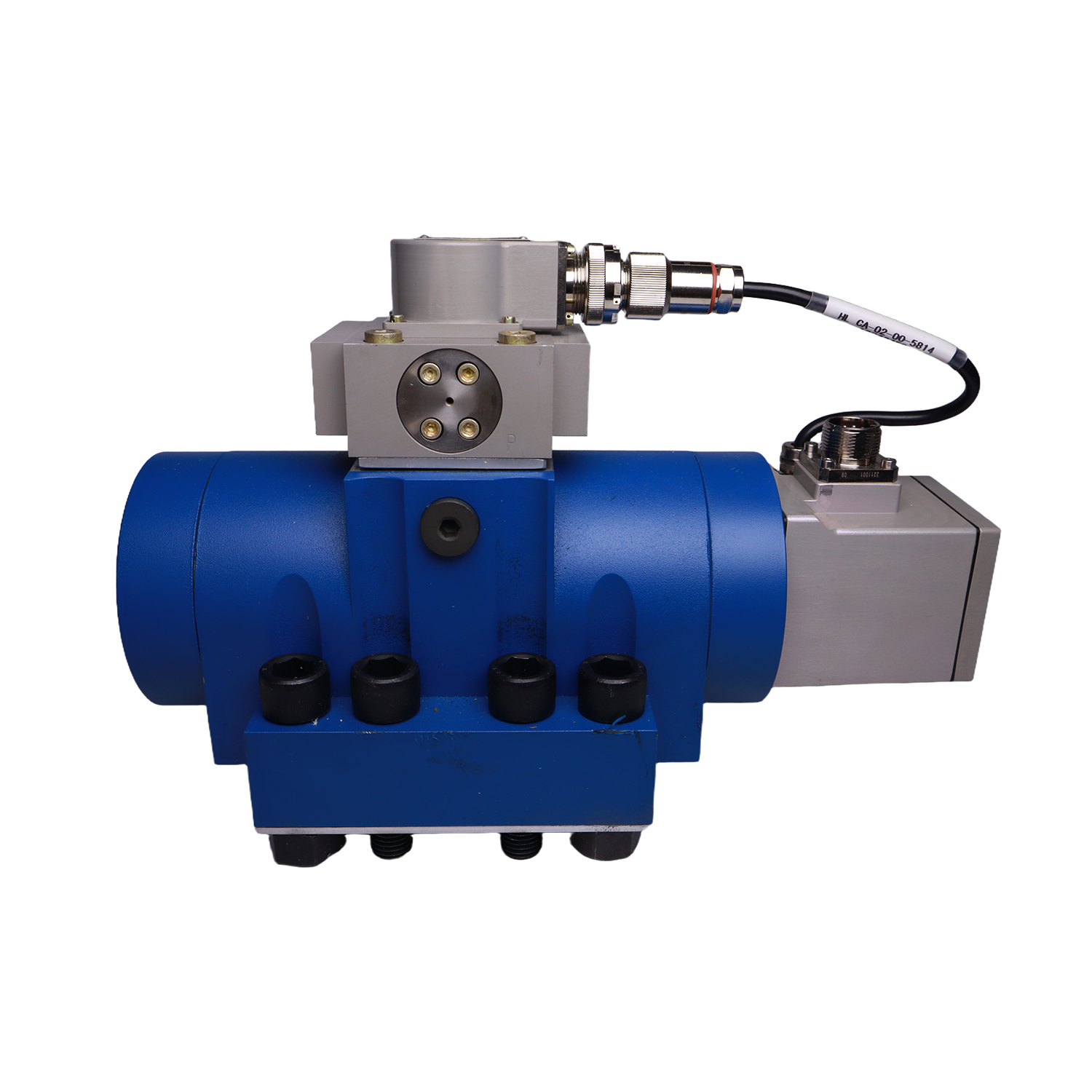

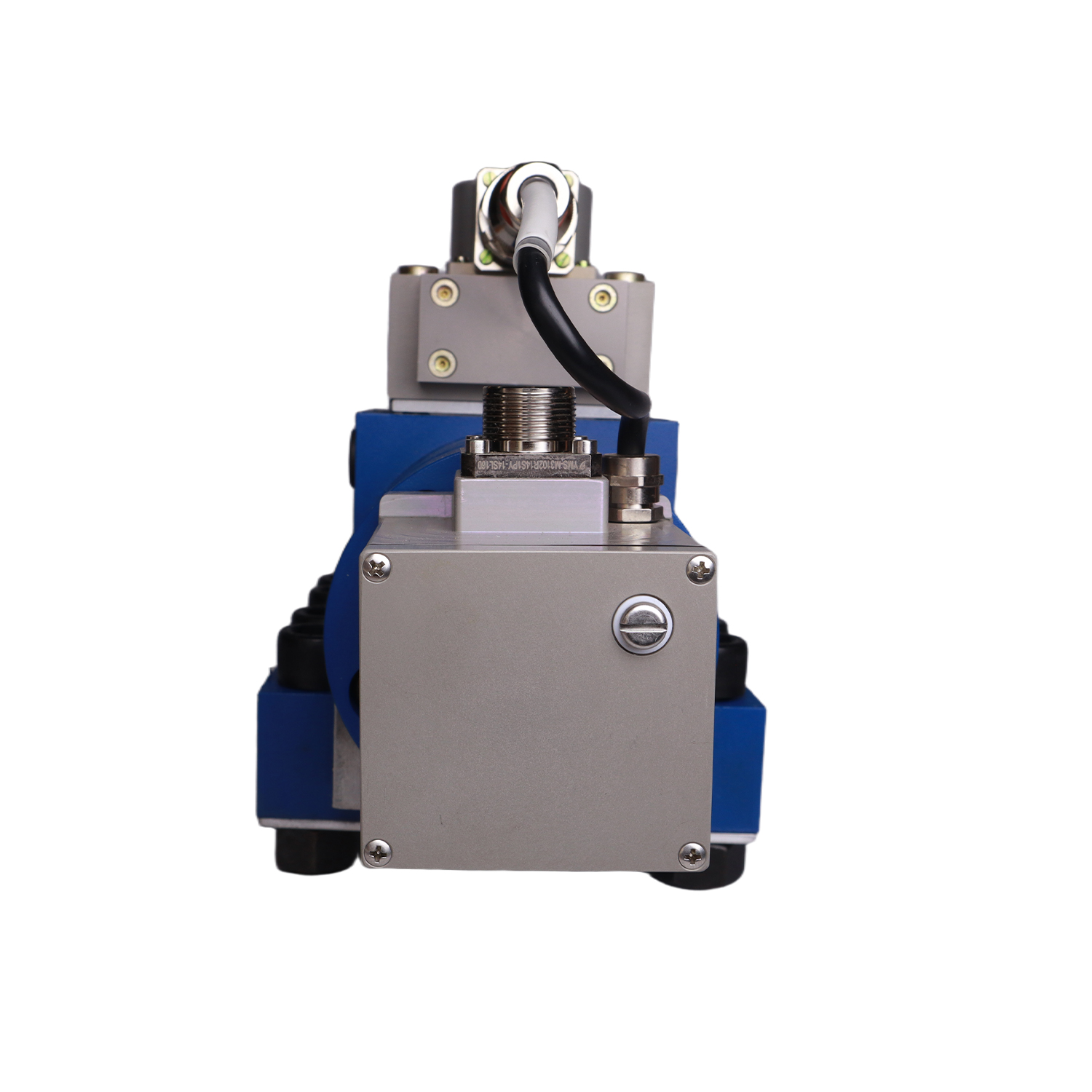

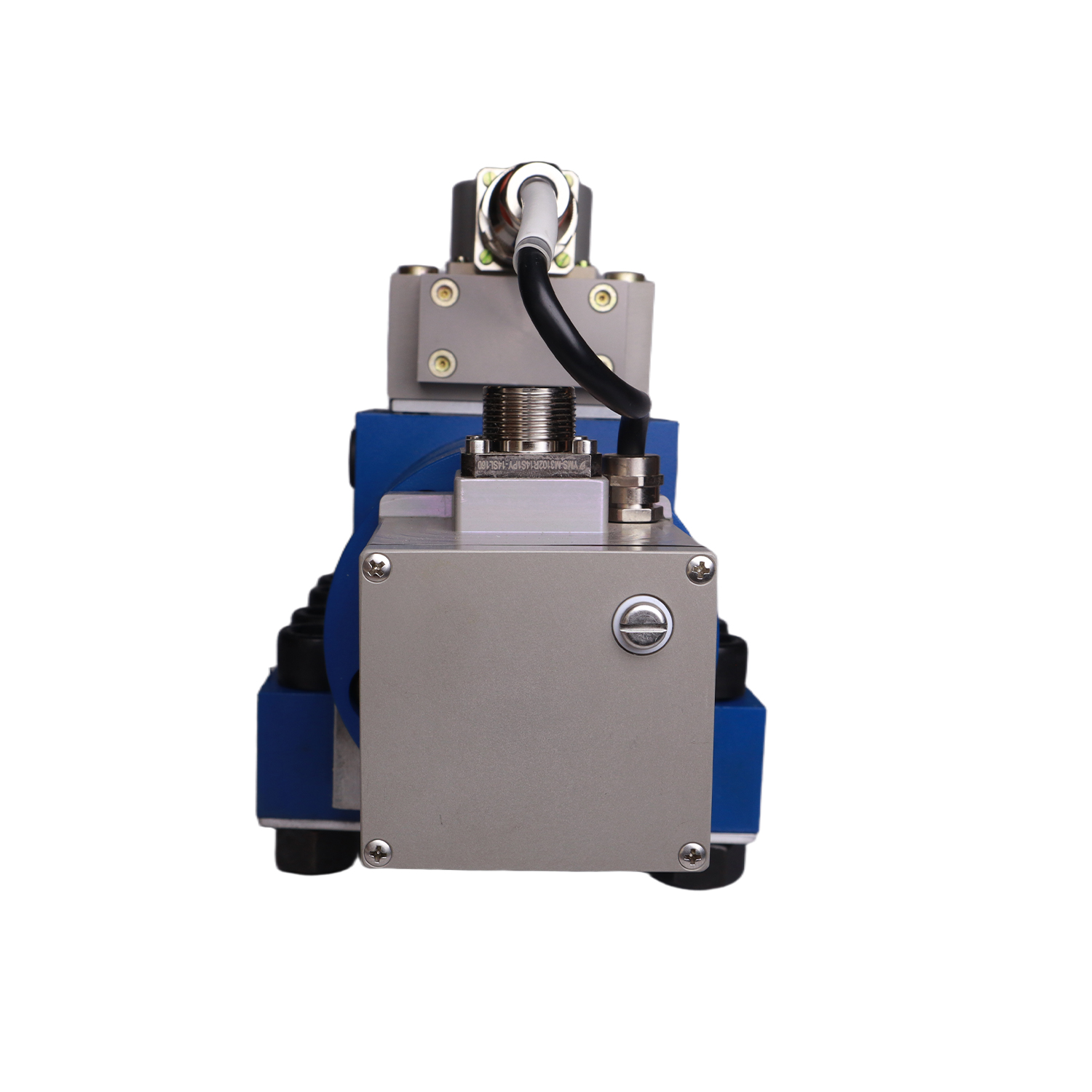

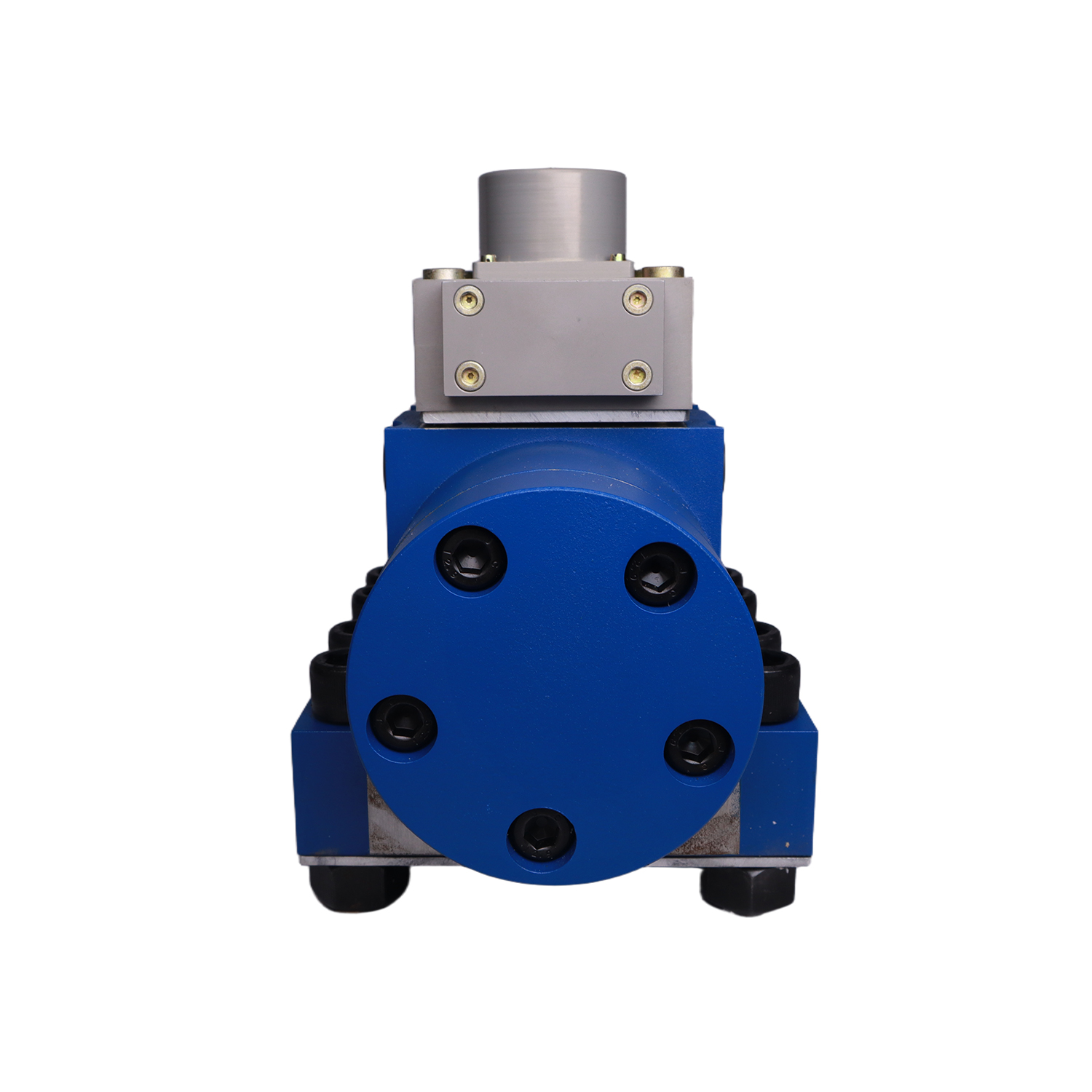

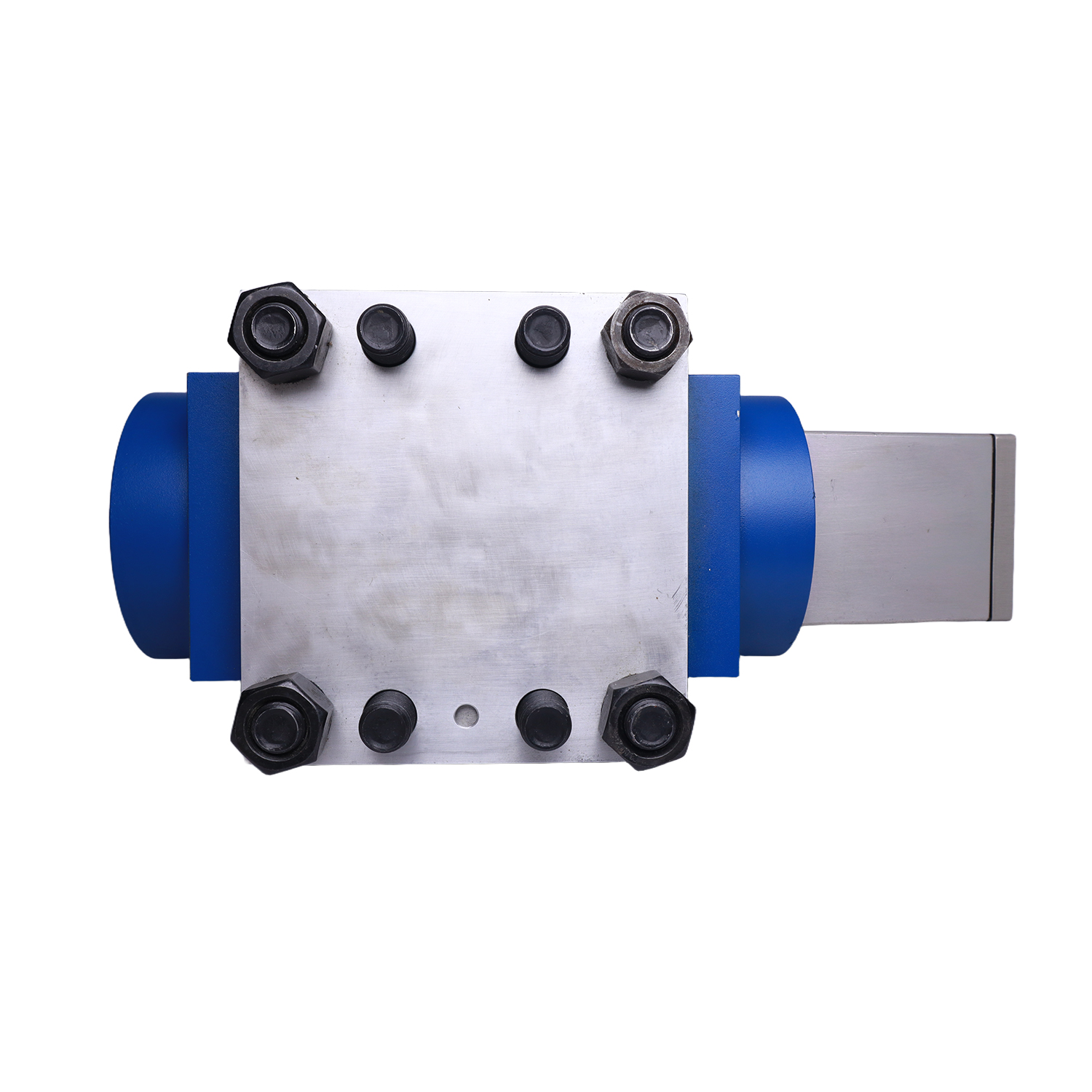

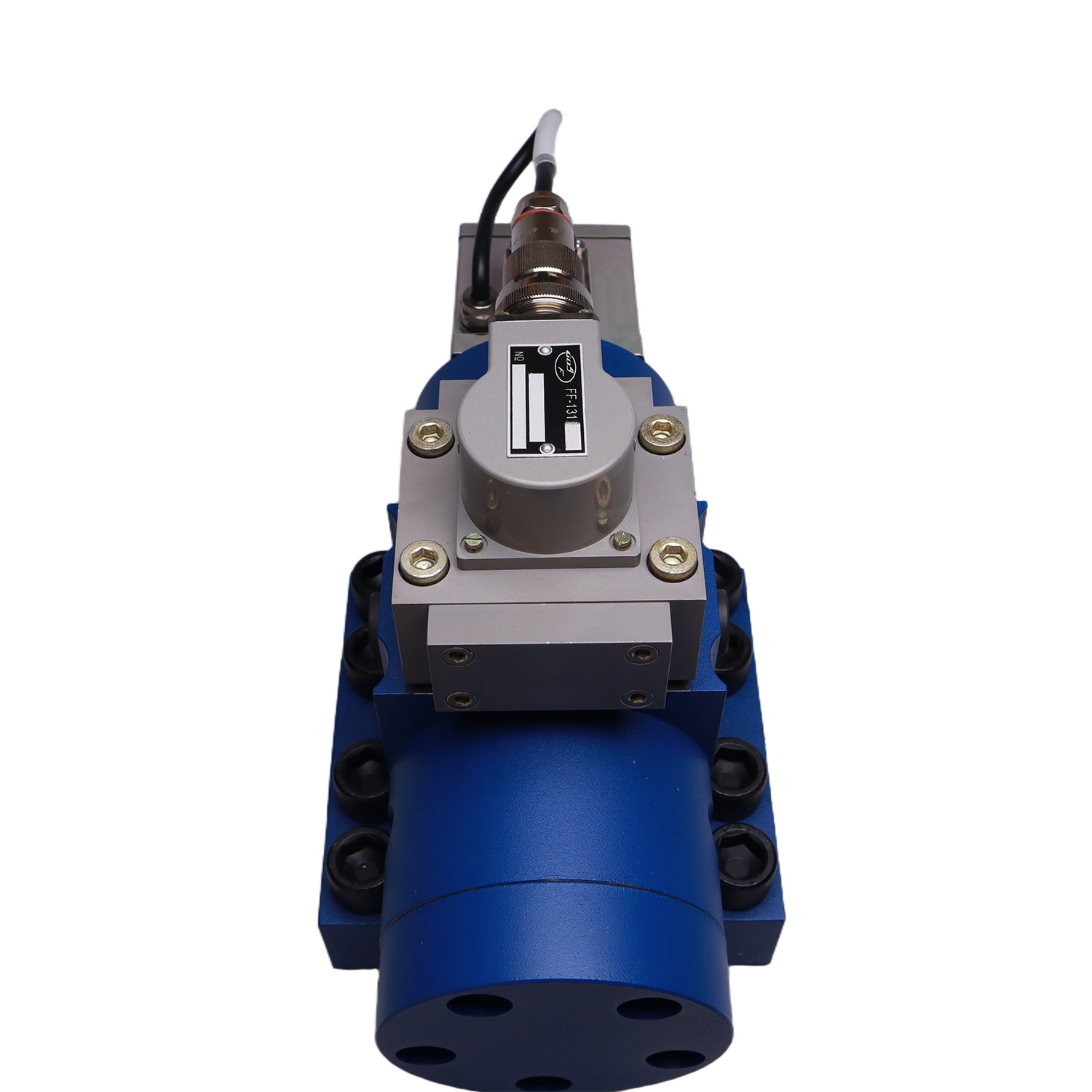

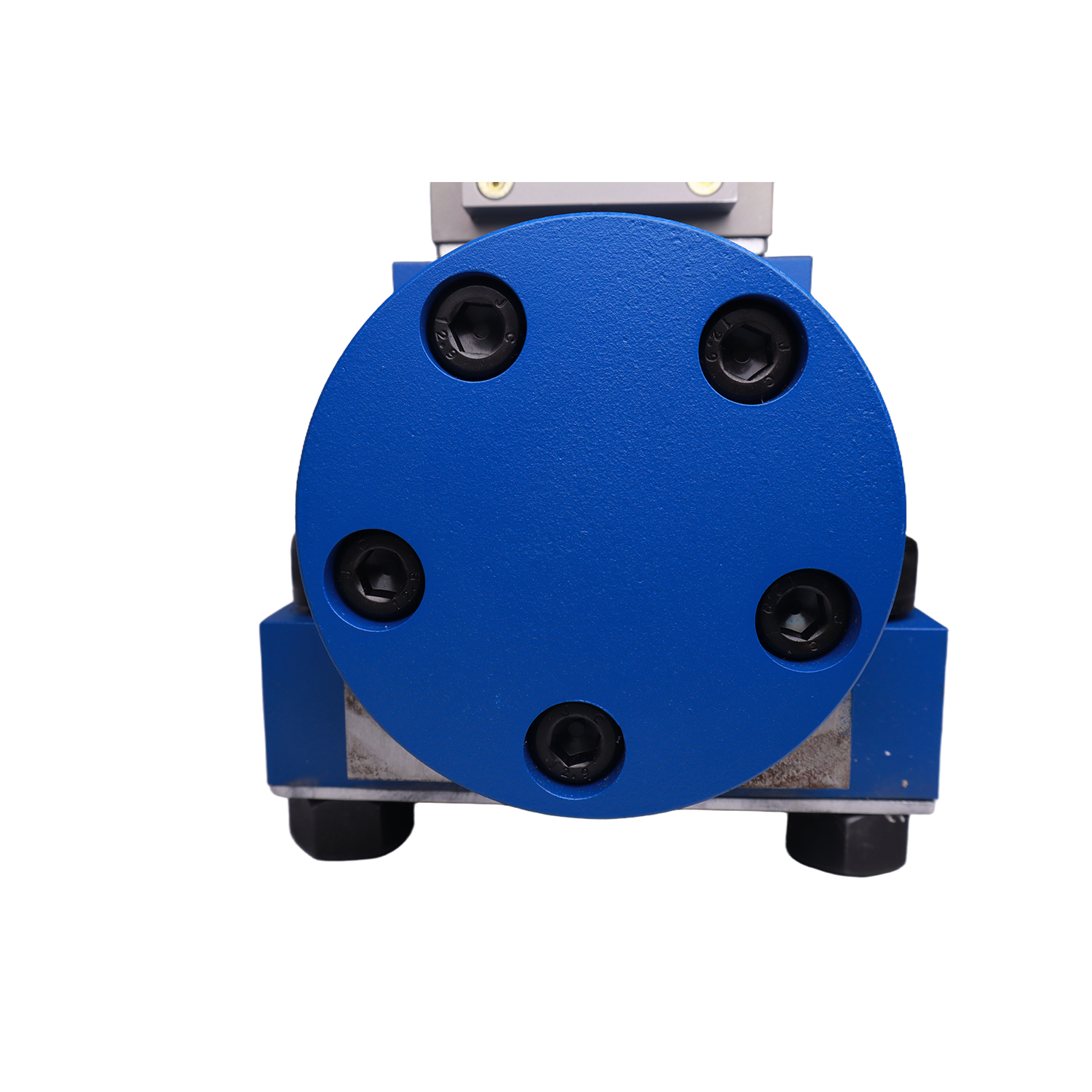

The FF-792 series electro-hydraulic servo valve is an electric feedback three-stage nozzle baffle high flow servo valve, with a flow rate of 400L/min under a pressure difference of 7MPa 630L/min, 800L/min, and 1000L/min. This type of servo valve uses a two-stage dual nozzle baffle servo valve as the pilot valve, with fast response and high dynamic performance. The LVDT valve core position sensor is used internally for position closed-loop control, resulting in small hysteresis, high resolution, and good repeatability accuracy. Compared to two-stage jet tube high flow servo valves, its dynamic response is higher. This series of three-stage servo valves features both high flow rate and high dynamic response.

The internal and external oil supply of the pilot stage is available for selection, and the control box is designed with an external electrical zero position adjustment device for more convenient use. At the same time, according to the requirements, the safety position of the valve core can be customized after power-off and pressure interruption. Suitable for industries such as steel metallurgy.

Product Features:

● Large static traffic and high dynamic response

●Internal integrated controller, combined with LVDT and other components to form an electro-hydraulic servo valve internal closed-loop

control

● Good output linearity

●High resolution, small hysteresis loop

●The pilot inlet and return oil can be controlled externally

● External electrical zeroing

Technical Parameter:

Item | Unit Of Measurement

| FF-792 Series |

Oil Supply Pressure Range | MPa | ≤31.5 |

Rate Supply Pressure Ps | MPa | 21 |

bar | 210 |

psi | 3050 |

Rate Flow Qn(±10%) △PN=7MPa | L/min | 400 | 630 | 800 | 1000 |

gpm | 105.7 | 166.4 | 211.3 | 264.1 |

Hysteresis Loop | % | ≤0.5 |

Resolution Ratio | % | ≤0.2 |

Nonlinearity | % | ≤7.5 |

Asymmetric Degree | % | ≤10 |

Pressure Gain | % | ≥30 |

Internal Leakage

| L/min | ≤10 | ≤14 | ≤14 | ≤14 |

gpm | ≤2.64 | ≤3.70 | ≤3.70 | ≤3.70 |

Null Bias | % | ≤±3 |

Overlap | % | ≤±2.5 |

Null Shift With Temperature (Temperature Changes By 55 ℃ Every Time)

| % | ≤±4 |

Step Response | ms | 4~12 |

Spool Displacement | mm | 1.8 | 1.9 | 2.6 | 4.0 |

Valve Core Driving Area | cm² | 3.8 | 7.14 |

Pilot Stage Flow Rate △PN=21MPa | L/min | 32.5 |

gpm | 8.59 |

Net Weight | kg | 17 |

Applications:

Electro hydraulic servo valve is a key component in electro-hydraulic servo control. It is a hydraulic control valve that receives analog electrical signals and outputs modulated flow and pressure accordingly. Electro hydraulic servo valves have the advantages of fast dynamic response, high control accuracy, and long service life, and have been widely used in electro-hydraulic servo control systems in aviation, aerospace, shipbuilding, metallurgy, chemical and other fields.