In modern manufacturing, lathes, as an important tool for mechanical processing, the stability and reliability of their performance directly relate to the quality of the product. As a key component in the lathe, the performance of the hydraulic servo valve directly affects the processing accuracy and production efficiency of the lathe. Therefore, choosing a suitable hydraulic servo valve is crucial. This article will provide a technical selection guide for the application of YUKEN high-performance hydraulic servo valves in ordinary lathes.

One, Basic Knowledge of Hydraulic Servo Valve

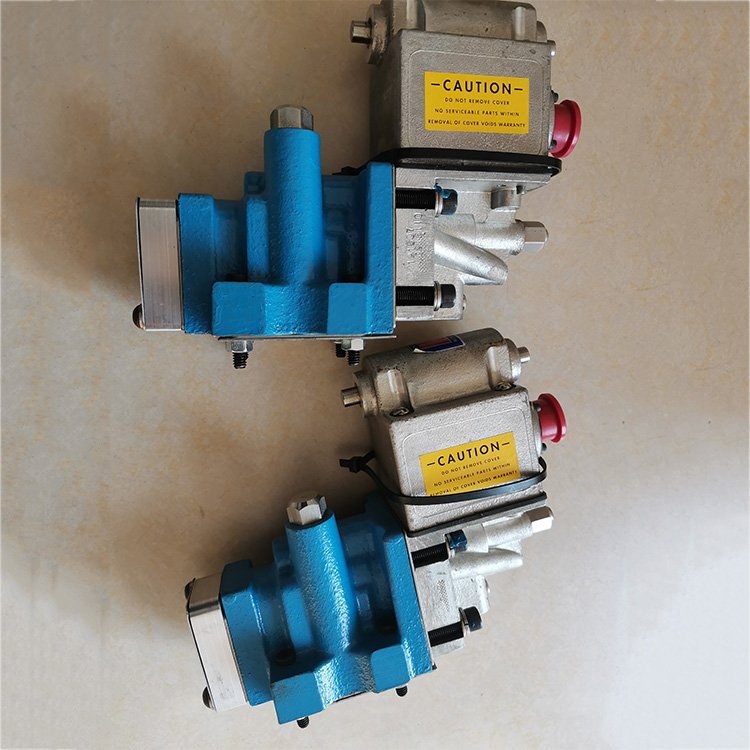

The hydraulic servo valve is a control valve used to control the flow direction and speed of fluid in the hydraulic system. It controls the hydraulic system accurately through electronic signals and is suitable for occasions that require high precision and high response speed. As a well-known hydraulic component supplier, YUKEN's high-performance hydraulic servo valves enjoy a good reputation in the domestic and international markets.

Two, Characteristics of YUKEN High-Performance Hydraulic Servo Valve

High precision: YUKEN hydraulic servo valves use advanced electronic control technology to provide high-precision control, ensuring the processing accuracy of the lathe.

High response speed: YUKEN hydraulic servo valves have a fast response speed, which can meet the requirements of the lathe for control speed and accuracy.

High reliability: YUKEN hydraulic servo valves use high-quality materials and manufacturing processes to ensure their long-term stable operation.

Easy to integrate: YUKEN hydraulic servo valves have good electrical interfaces, which are easy to integrate with other control systems.

which are easy to integrate with other control systems.

Three, Technical Selection Guide for YUKEN High-Performance Hydraulic Servo Valve

Understand the specific needs of the lathe: according to the working load, processing accuracy requirements, production efficiency requirements, and other information of the lathe, choose a suitable hydraulic servo valve.

Evaluate the performance parameters of the hydraulic servo valve: including control accuracy, response speed, durability, etc., and choose a hydraulic servo valve that meets the needs of the lathe.

Consider the integration and compatibility of the system: choose hydraulic servo valves with good electrical interfaces to ensure that they are easy to integrate with other control systems.

Consider after-sales service: choose suppliers that provide good after-sales service to ensure that technical support can be obtained in a timely manner when problems arise during use.

In summary, choosing the appropriate YUKEN high-performance hydraulic servo valve is of great significance for improving the performance and accuracy of ordinary lathes. During the selection process, it is necessary to fully consider the specific needs of the lathe, the performance parameters of the hydraulic servo valve, as well as the integration and compatibility of the system, to ensure that the selected hydraulic servo valve can meet the needs of the lathe.