Hydraulic system is a technical system that uses liquid pressure energy to transmit power and control, and is widely used in construction machinery, aerospace, metallurgical equipment, automobile industry and other fields. Its core principle is based on Pascal's law, that is, in a closed container, the pressure exerted on the liquid can be transmitted to all parts of the liquid equally. Hydraulic system realizes energy transmission and control through the pressure and flow of liquid, which has the advantages of compact structure, stable transmission, fast response and easy automation.

First, the basic composition of thehydraulicsystem

A complete hydraulic system usually consists of the following five basic components:

1. Power components:

The power element is mainly a hydraulic pump, whose function is to convert mechanical energy into pressure energy of liquid and provide power for the system. Common hydraulic pumps are gear pump, vane pump, piston pump, etc., and the corresponding types are selected according to different working pressures and uses.

2. Executive components:

The actuator includes hydraulic cylinder and hydraulic motor, whose function is to convert the pressure energy of liquid into mechanical energy again and drive the load to do linear motion or rotary motion. For example, hydraulic cylinders are used to push mechanical arms or lifting platforms, while hydraulic motors are often used to drive rotary devices. 3. Control elements:

3. Control elements:

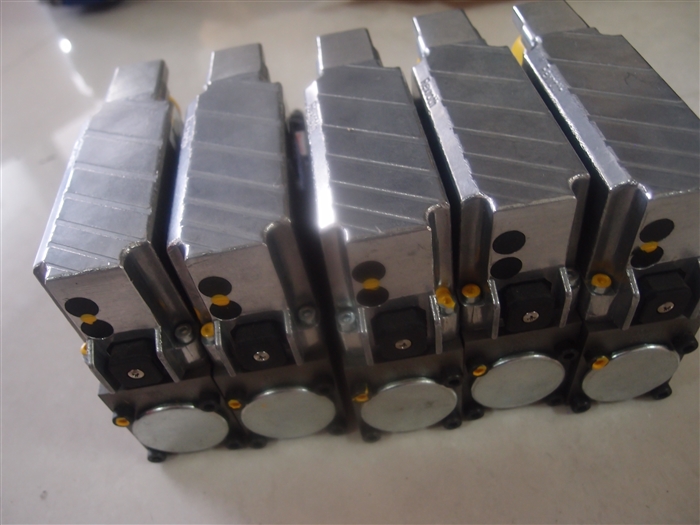

Control components mainly include various hydraulic valves, such as directional control valve, pressure control valve and flow control valve. They are used to control the flow direction, pressure and flow rate of liquid, so as to accurately control the running state of the actuator and realize the automation and accurate control of the system.

4. Auxiliary components:

Auxiliary components, including oil tank, tubing, oil filter, cooler, accumulator, etc., are mainly used for storage, transportation, filtration, cooling and energy storage of hydraulic oil, and are an important part to ensure the normal operation of the system.

5. Working medium:

The working medium is usually hydraulic oil, which not only serves as the medium of energy transmission, but also plays the role of lubrication, rust prevention, sealing and cooling. The performance of hydraulic oil directly affects the efficiency and life of the whole system, so the appropriate model must be selected according to the working conditions.

Second, the working principle of hydraulic system

The working principle of the hydraulic system can be summarized as follows: the power element (hydraulic pump) converts the mechanical energy provided by the motor or engine into the pressure energy of the liquid; After the pressure and flow are adjusted by the control element, the high-pressure liquid drives the executive element (hydraulic cylinder or motor) to move to complete the required mechanical movement; Auxiliary components ensure the stability and safety of the system; The whole process realizes efficient energy transmission and control in the circulating flow of hydraulic oil.

To sum up, hydraulic system plays an irreplaceable role in modern industry because of its high efficiency, reliability and flexibility. With the continuous development of hydraulic technology, the trend of intelligence, energy saving and integration is increasingly obvious, which provides a strong guarantee for the performance improvement of various mechanical equipment.

Composition principle of hydraulic system

2025-08-26 Visits: