The electro-hydraulic servo valve is an important control component in the electro-hydraulic servo control system, which plays a role in electro-hydraulic conversion and power amplification in the system. Specifically, during system operation, it directly receives electrical signals transmitted by the system and converts them into proportional signals with corresponding polarity that can control the load flow or load pressure of the electro-hydraulic servo valve, thereby enabling the system to output a large hydraulic power to drive the corresponding actuator. The performance and reliability of electro-hydraulic servo valves will directly affect the performance and reliability of the system, and are key components that attract attention in electro-hydraulic servo control systems.

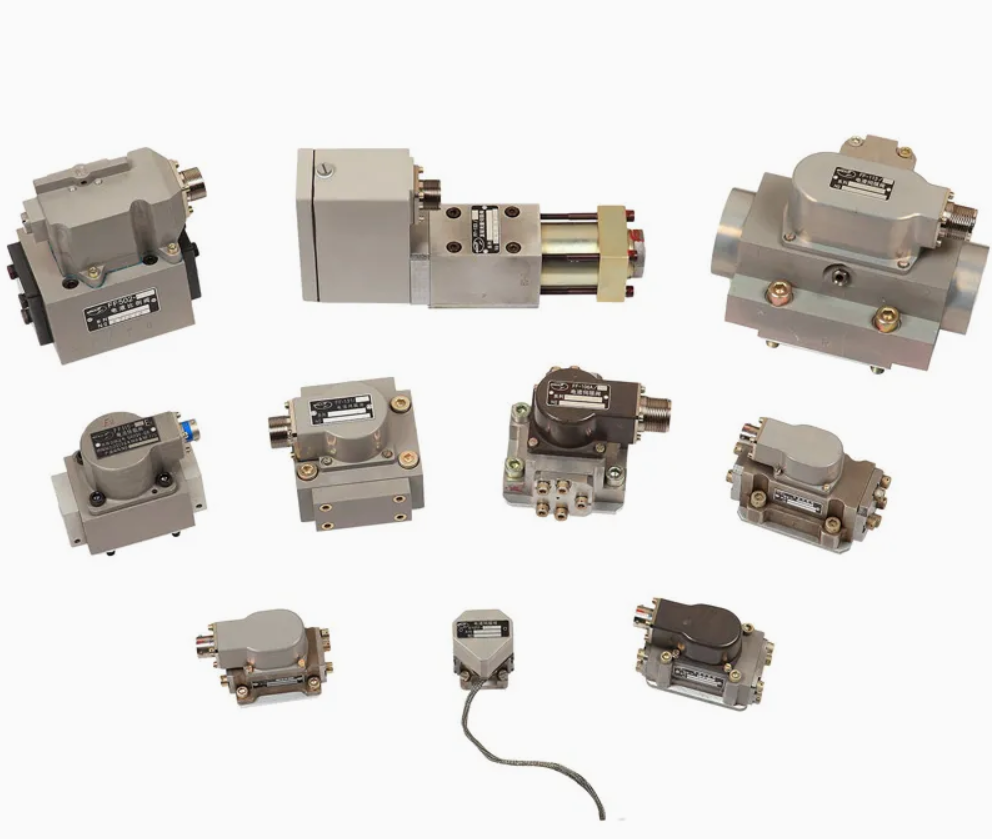

Common force feedback two-stage dual nozzle baffle flow servo valves include FF-101 series, FF-102 series, FF-106 series, FF-113 series, and FF-131 series. Under a pressure difference of 7 MPa, the flow rate range is 0.5-250 L/min. The spray stop servo valve has the advantages of high dynamic response, compact structure, light weight, stable and reliable performance, and long service life, and is suitable for hydraulic systems such as robot control, experimental equipment, and power equipment.

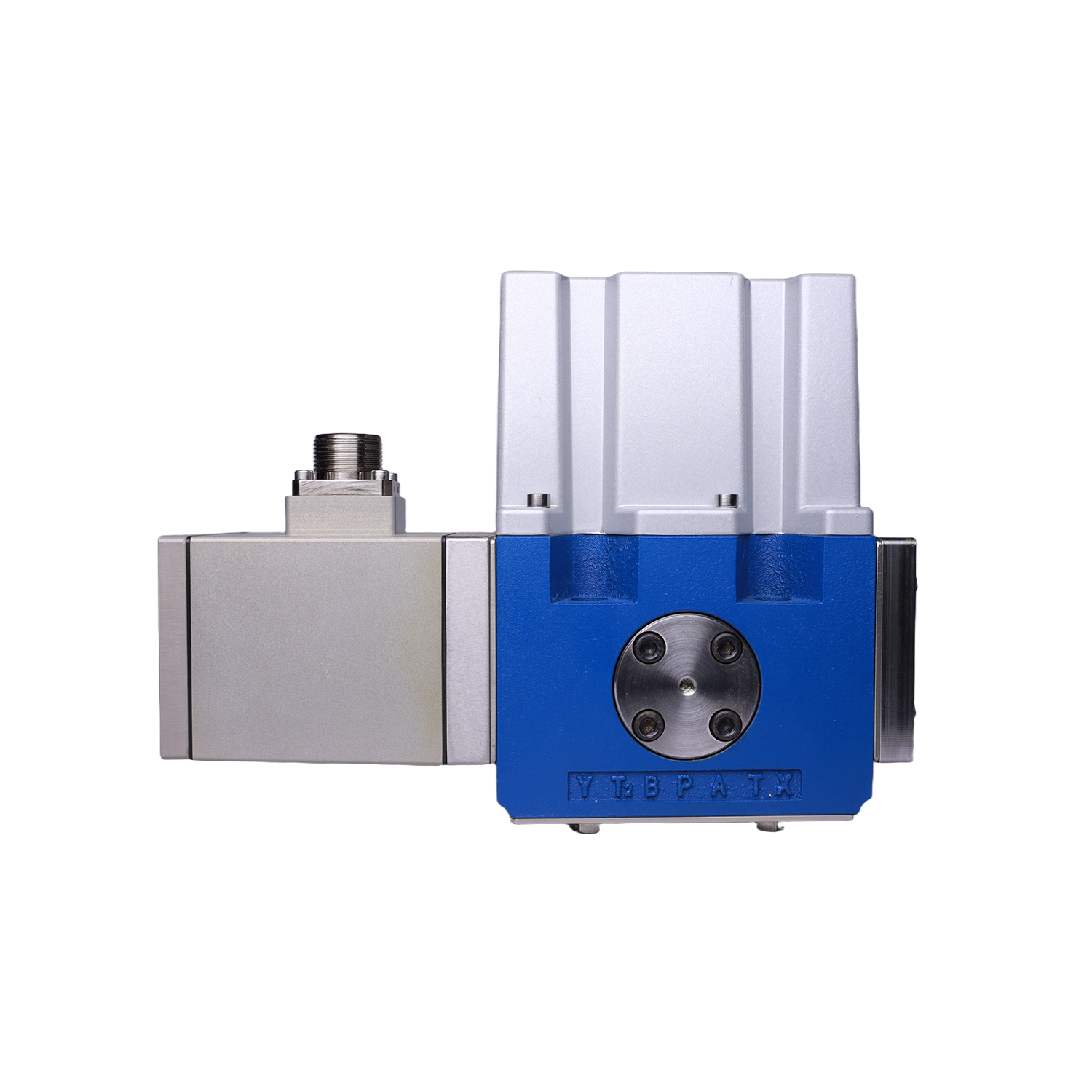

The common two-stage jet tube flow servo valves include FF-661 series, FF-662D series, FF-663L series, and FF-664L series. The latter three have a larger flow rate and can be classified as high flow servo valves. Under a pressure difference of 1 MPa, the flow rate range is 8-550 L/min. This type of servo valve adopts a high flow jet tube to drive the servo valve core, with strong anti pollution ability. Internally, LVDT displacement sensors are used for valve core position closed-loop, resulting in small hysteresis, high resolution, and good repeatability accuracy. The inlet and outlet oil form of the pilot valve can be selected by the user as internal control or external control. The product is equipped with an electrical zero adjustment structure on the outside, which is convenient for users to use. According to user needs, the power-off valve core can be set to center or the valve core can move to a certain extreme safety position, which can keep the system in a set safe state after accidental power-off. It is suitable for industries such as steel and metallurgy.

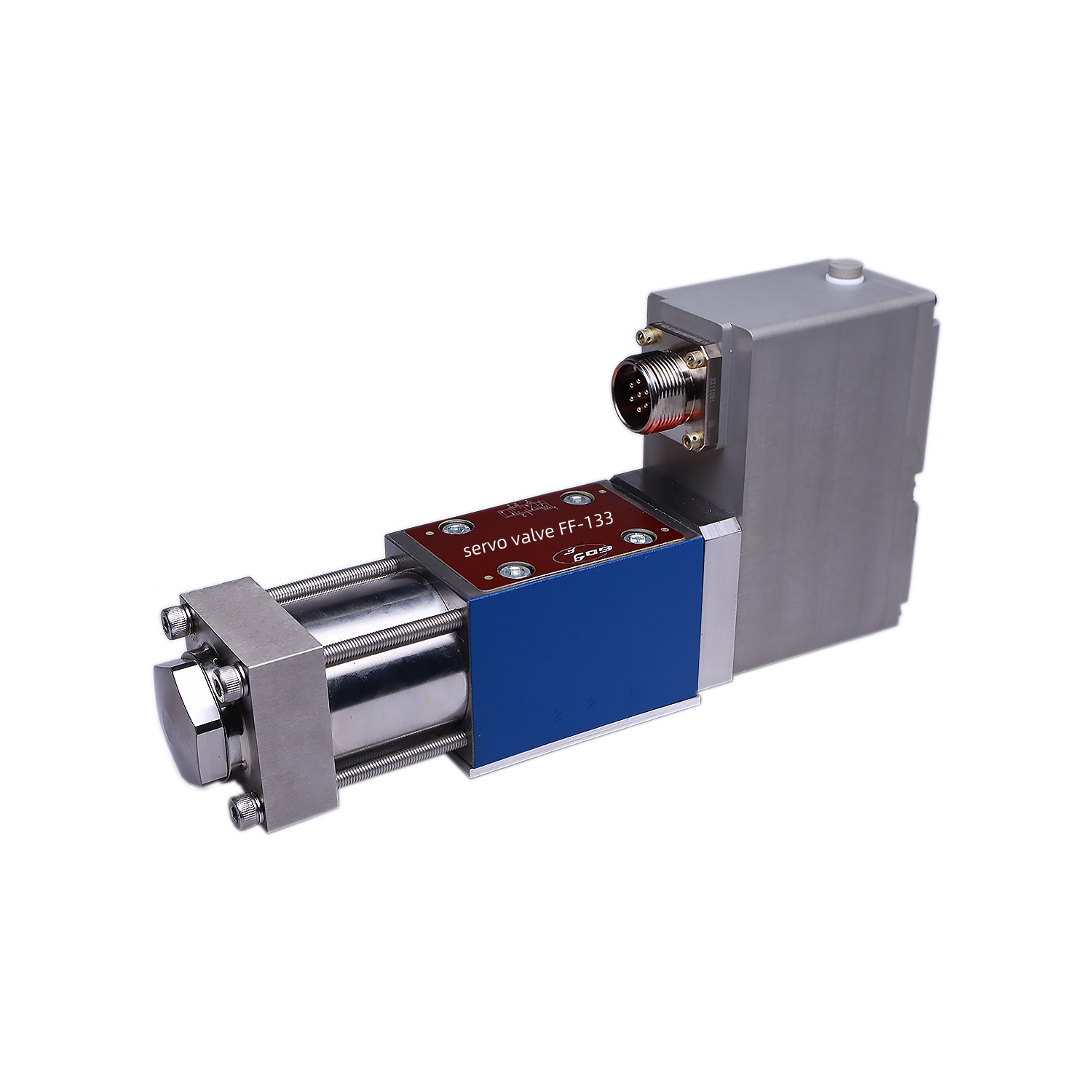

Common linear direct drive servo valves include the FF-133 and FF-134 series. Under a pressure difference of 7 MPa, the flow rate range is 5-100 L/min. Due to the lack of a pilot stage and internal structures such as throttling holes, the linear direct drive servo valve has low leakage, low hydraulic power consumption, and strong anti pollution ability. The servo valve is directly driven by a linear force motor, and the valve core position is closed loop internally through LVDT displacement sensors. Therefore, it has small hysteresis, high resolution, good repeatability, and high dynamics. The reduction of system oil supply pressure has little impact on dynamics. According to user needs, power-off failure centering or fixed bias can be set to keep the system in a pre-set safe state after unexpected power failure. The product has an external electrical zero adjustment function, which is convenient for users to adjust on their own. The product shell is made of stainless steel or cast iron, with high structural strength and high pressure resistance.

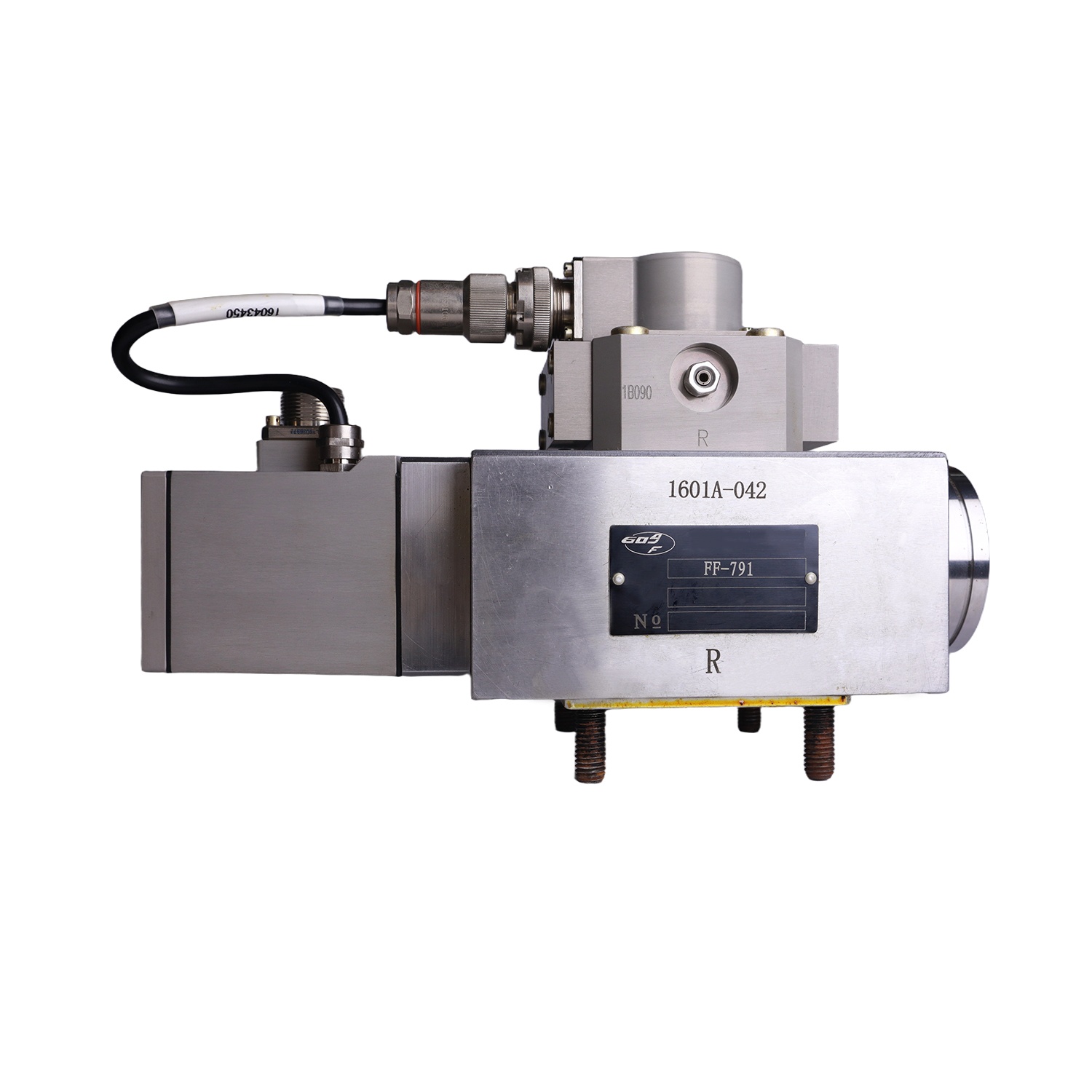

Common three-stage nozzle baffle high flow servo valves include FF-791 series, FF-792 series, FF-662P series, FF-663P series, and FF-664P series. Under a pressure difference of 1 MPa, the flow rate range is 40-550 L/min. The three-stage nozzle baffle high flow servo valve adopts a two-stage dual nozzle baffle servo valve as the pilot valve, and the valve core position is closed loop through LVDT displacement sensor. It has the characteristics of high static flow rate, good output linearity, high resolution, and small hysteresis loop. Compared with two-stage jet tube high flow servo valves, its dynamic response is higher. This type of three-stage servo valve has the characteristics of both high flow rate and high dynamic response. The inlet and outlet oil form of the pilot valve can be selected by the user as internal control or external control. The product is equipped with an electrical zero adjustment structure on the outside, which is convenient for users to use. The same applies to the metallurgical and steel industries.